Everything You Need To Know About Ammonium Hydroxide Waste Disposal

October 22, 2025

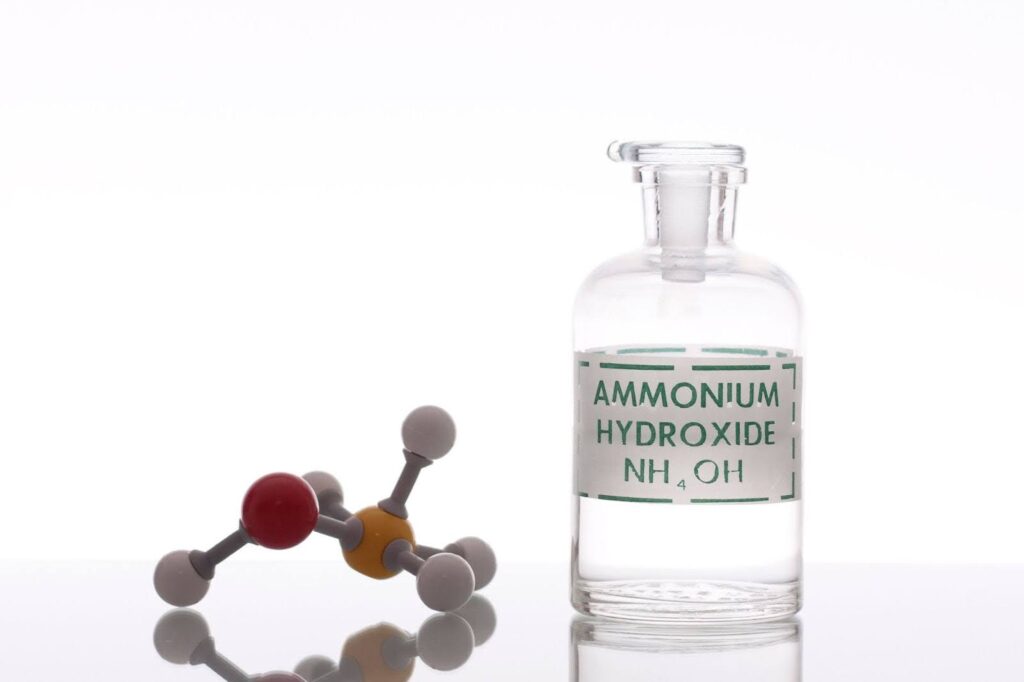

Ammonium hydroxide, or NH₄OH, is a liquid mixture of ammonia and water, used in industrial plants and household cleaning products alike.

When ammonium hydroxide becomes waste, it turns from useful to harmful. Improper ammonium hydroxide waste disposal can contaminate water, degrade soil, and pose risks to anyone exposed to it.

This guide explains what ammonium hydroxide is, why correct disposal matters, and how to manage it safely and legally.

Need help with ammonium hydroxide waste disposal? Reach out GTE Singapore through our contact form or email us at sales@gte.sg to enquire more.

What Is Ammonium Hydroxide?

Ammonium hydroxide is a chemical solution produced when ammonia gas dissolves in water. It functions as a weak base and is commonly used for cleaning, neutralising acids, and manufacturing other chemicals.

- Chemical Properties

It has alkaline characteristics and releases ammonia vapour when exposed to air. In water, it can raise pH levels quickly. Its corrosive nature means it can damage skin, eyes, and certain metals on contact.

- Common Uses

Industries use ammonium hydroxide in cleaning, textile processing, fertiliser production, and laboratory work. Some household products also contain small amounts of it, especially surface and glass cleaners.

- Potential Hazards

Exposure can cause irritation to skin, eyes, and the respiratory tract. When released into the environment, it can harm aquatic life and disturb natural pH balance. Careful handling and disposal are essential to prevent accidents and contamination.

(Source: Envato)

(Source: Envato)

Why Ammonium Hydroxide Waste Disposal Is a Serious Matter

Ammonium hydroxide may seem harmless in small amounts, but once discarded without control, it becomes a source of environmental and health problems.

Environmental Risks

When ammonium hydroxide enters drains or soil without treatment, it alters the pH of nearby water sources. This imbalance can kill fish, damage plant roots, and weaken soil health. Even low concentrations can cause lasting harm to rivers and groundwater.

Health Hazards

Ammonia vapour irritates the skin, eyes, and lungs. Prolonged exposure may cause breathing difficulties or chemical burns. Handling ammonium hydroxide waste without protection endangers workers and nearby communities.

Regulatory Importance

In Singapore, ammonium hydroxide waste is treated as toxic industrial waste (TIW) under the Environmental Public Health (Toxic Industrial Waste) Regulations. These regulations fall under the Environmental Protection and Management Act (EPMA), which oversees the control of hazardous substances.

Businesses that generate ammonium hydroxide waste must either treat it in a licensed on-site facility or hand it over to a NEA-approved toxic industrial waste collector. Transporting the waste requires approval, and containers must carry proper hazard labels according to Singapore Standard SS 586.

For international trade, the Hazardous Waste (Control of Export, Import and Transit) Act enforces the Basel Convention, which prevents unsafe cross-border movement of hazardous waste.

Non-compliance can result in heavy fines, license suspension, or prosecution. Following the correct ammonium hydroxide waste disposal process protects both the environment and your business.

(Source: Envato)

(Source: Envato)

Identifying Ammonium Hydroxide Waste

Knowing what counts as ammonium hydroxide waste is the first step towards safe handling and compliance. Not every residue is the same, and how you treat it depends on its strength, form, and source.

- Sources of Waste

Ammonium hydroxide waste often comes from industrial cleaning, chemical production, laboratory experiments, and wastewater treatment. It can appear as leftover solutions, used rinse water, or neutralisation residues. Even diluted traces in cleaning effluent count as controlled waste when generated in bulk. - Concentration and Quantity

Testing the pH and ammonia concentration helps determine how to manage the waste. High-strength solutions require neutralisation or collection by a licensed toxic industrial waste collector. Diluted waste may still need treatment before discharge, depending on NEA’s limits for ammonia nitrogen in trade effluent. - Labelling and Documentation

All containers storing ammonium hydroxide waste must be clearly labelled with the chemical name, hazard symbols, and waste code in line with Singapore Standard SS 586.

Each container should carry a Material Safety Data Sheet (MSDS) and record details such as the waste source, date of generation, and quantity.Businesses must also maintain waste tracking records, as required by the Environmental Public Health (Toxic Industrial Waste) Regulations.

These records show how much waste was produced, who transported it, and where it was treated or disposed of. Proper documentation ensures accountability and smooth NEA audits.

(Source: Envato)

(Source: Envato)

Safe Disposal Methods

Safe ammonium hydroxide waste disposal begins with knowing what you can do in-house and when to call a licensed collector. The method depends on the waste’s concentration, volume, and local discharge limits.

- Neutralisation Process

Ammonium hydroxide can be neutralised with a weak acid such as acetic or citric acid. Add the acid gradually while stirring, and monitor the pH until it reaches a neutral level of around 7.

Confirm neutrality with a pH meter or test strips before any further action. Wear proper safety gear, including gloves, goggles, and protective clothing. - Dilution and Controlled Discharge

Some facilities discharge neutralised wastewater into public sewers, but only under strict conditions. In Singapore, this is regulated under the Sewerage and Drainage Act and the Trade Effluent Regulations.

The National Environment Agency (NEA) sets limits for ammoniacal nitrogen, typically not exceeding 50 mg/L in trade effluent. Before discharge, companies must obtain approval and keep discharge records for inspection. - Chemical Treatment

For concentrated or large volumes of ammonium hydroxide waste, chemical treatment is safer. This process converts the ammonia into non-hazardous compounds, reducing environmental impact.

Such treatment must be done in an approved facility under NEA supervision or by a licensed toxic industrial waste collector. - Professional Hazardous Waste Services

If your business produces more than small lab-scale quantities, hire an NEA-licensed toxic industrial waste collector.

These contractors handle collection, transportation, treatment, and disposal in compliance with Singapore’s Environmental Public Health (Toxic Industrial Waste) Regulations. Each collection is documented with a consignment note to prove proper disposal.

Proper ammonium hydroxide waste disposal keeps your operations compliant and protects public health. It also demonstrates corporate responsibility by ensuring that no harmful substances enter the environment untreated.

(Source: Envato)

(Source: Envato)

Eco-Friendly and Sustainable Alternatives

Reducing ammonium hydroxide waste starts long before disposal. The most effective strategy is to limit how much you generate and to reuse what you can.

- Waste Minimisation

Review your chemical use regularly. Use the lowest concentration of ammonium hydroxide needed for each task. Replace open containers with sealed systems to reduce evaporation losses. Routine monitoring can prevent overuse and lower waste output. - Substitution

Where possible, switch to milder alkaline cleaners or process aids that perform the same function. Many industries now use biodegradable or low-toxicity agents that deliver similar results without generating hazardous waste. - Recycling and Recovery

Ammonia recovery systems can capture vapours or extract ammonia from wastewater through stripping or absorption processes.

Some local facilities, such as water-reclamation plants, already recover ammonia for reuse in fertiliser production or other industrial processes. Engaging recycling partners approved by the National Environment Agency (NEA) helps ensure compliance. - Corporate Sustainability Initiatives

Under Singapore’s Zero Waste Masterplan and Green Plan 2030, companies are encouraged to adopt circular waste management practices.

Tracking chemical inventories, setting reduction targets, and publishing sustainability reports can strengthen environmental credentials while lowering costs.

Eco-friendly ammonium hydroxide waste management protects the environment and improves efficiency and supports Singapore’s broader move towards a low-waste economy.

Conclusion

Responsible ammonium hydroxide waste disposal reflects good management and accountability. By reducing use, neutralising safely, and engaging licensed collectors, businesses prevent pollution and avoid costly penalties.

If you handle or produce this chemical, review your waste procedures today. When in doubt, consult the National Environment Agency (NEA) or a certified toxic industrial waste collector for guidance. Proper disposal ensures that what once served a purpose doesn’t become a long-term problem.

Need help with ammonium hydroxide waste disposal? Reach out GTE Singapore through our contact form or email us at sales@gte.sg to enquire more.

GreenTec Energy Pte Ltd (GTE) is a waste management company located in Tuas, Singapore.

GreenTec Energy Pte Ltd (GTE) is a waste management company located in Tuas, Singapore.

Our service includes Industrial waste, Oily waste, Marine waste.

To provide a hassle free solution to our customer is always the key approach and to ensure a win-win situation towards. As a NEA approved environmental company in Singapore, we take all our services seriously and to ensure maximum safety with compliances applied. Every step of our disposal processes are also designed to meet NEA & SCDF requirements, with latest treatment facilities and laboratories to test and treat all incoming waste before disposal.

GTE operates a total land area of about 100,000sqft at 14 Tuas South Street 12 Singapore 636953. With our comprehensive logistics and transportation fleet, we provide prompt and efficient services in transportation of waste to our premises.